- The correct use of the air shower can effectively control bacteria and dust

In much production work, due to the high requirements of the product, it is usually carried out under aseptic conditions during production and processing. Due to the presence of some impurities and bacterial particles in the working environment, this...

- Air filter replacement cycle for air shower room

You may find the performance of the filter in the air shower is particularly good after using it. Compared with other filters, it contains the primary air filter and the air filter, and has a two-in-one function. So let me introdu...

- The angle requirements of the air outlet of the air shower room

Press the up and down keys for about 10 seconds, the Chongqing air shower time can be adjusted. So what are the requirements?

The single-person double-air shower is a special passage set up for the staff to enter and exit the clean area, which ca... - The reason why the air shower room needs the primary filter and the high efficiency filter

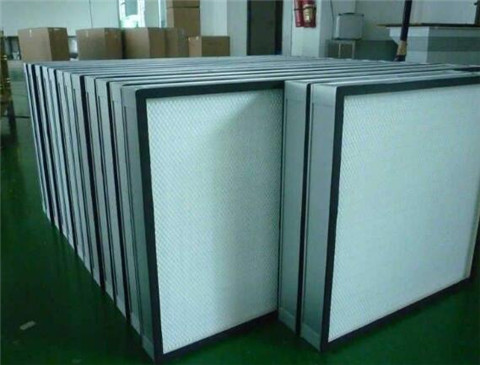

The air shower room in Chongqing must be equipped with primary efficiency filters and high efficiency filters to achieve the dust removal effect. The air shower room has a voice prompt system, which prompts people to complete the entire blowing and d...

- Clean room and sterile room needing to install air shower

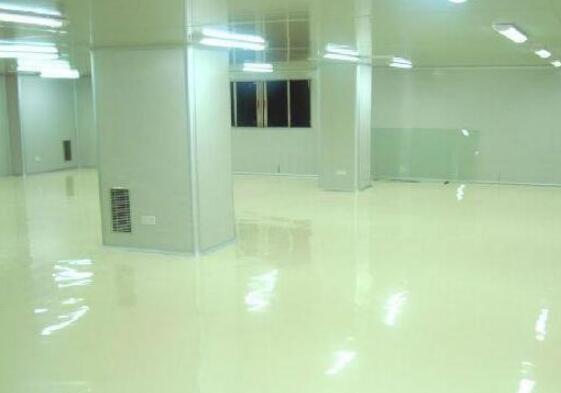

The general air shower room is a special channel specially set up for work management personnel and materials to enter the clean room. The main purpose of the company is to reduce the dust and bacteria we bring into the clean room when the staff and mater...

- The importance of airtight performance to stainless steel air shower

Nowadays, purification equipment is increasingly used in the production industry. The air shower room serving as an important throat of the clean room, when people or objects entering and exiting the clean room, the air shower room will be ...

Factors of airflow velocity in clean room engineering of purification engineering

information sources:www.xqfjhgc.com | Release time:2021-06-18

The air velocity inside the clean room in Chongqing should be determined according to the purpose of the clean room. It is not only affected by the amount of internal dust, but also by other factors. As far as the clean room engineering is concerned, the air velocity factors mainly include the following:

(1) Indoor pollution sources: building components, number and operational activities of personnel, process equipment, process materials and process itself are all sources of dust release, which vary greatly depending on the specific situation.

(2) Indoor air flow pattern and distribution: uniform and equal flow lines are required in one-way flow in the purification workshop, but it will be interfered by the layout and location of process equipment and personnel activities to form local vortices instead of single To flow requires filling and mixing to avoid dead ends and temperature stratification.

(3) Self-cleaning time control requirements: the accidental release or introduction of pollutants or interruption of air flow or intermittent convective air flow during normal operation or the movement of people and equipment in the dust-free workshop will cause the deterioration of the cleanliness. The self-cleaning time needed in restoring to the original cleanliness is determined by the airflow speed, and the control requirements for the self-cleaning time depend on the ability to withstand the impact of product quality and yield within this time frame.

(4) The efficiency of the final stage filter: Under a certain amount of indoor dust generation, a higher efficiency filter can be used to reduce the airflow speed. In order to save energy, you should consider using a higher efficiency filter and reducing the airflow speed, or using a lower efficiency filter and a higher airflow speed, so as to minimize the product of the flow and the resistance.

(5) Economy considerations: It is believed that in the purification workshop the excessive airflow speed will increase investment and operating costs. The appropriate airflow speed is a reasonable combination of the above factors. Excessive airflow is often unnecessary and may not be effective.

(6) For dust-free workshops with low cleanliness requirements, sometimes the number of air changes is determined by the requirements of indoor heat removal.

Related articles

Related products